Meta description (140–160 characters):

NANOTEC’s Green Extraction service isolates high-value actives from botanicals using supercritical CO₂ and subcritical-water methods, safe, eco-friendly, and market-ready.

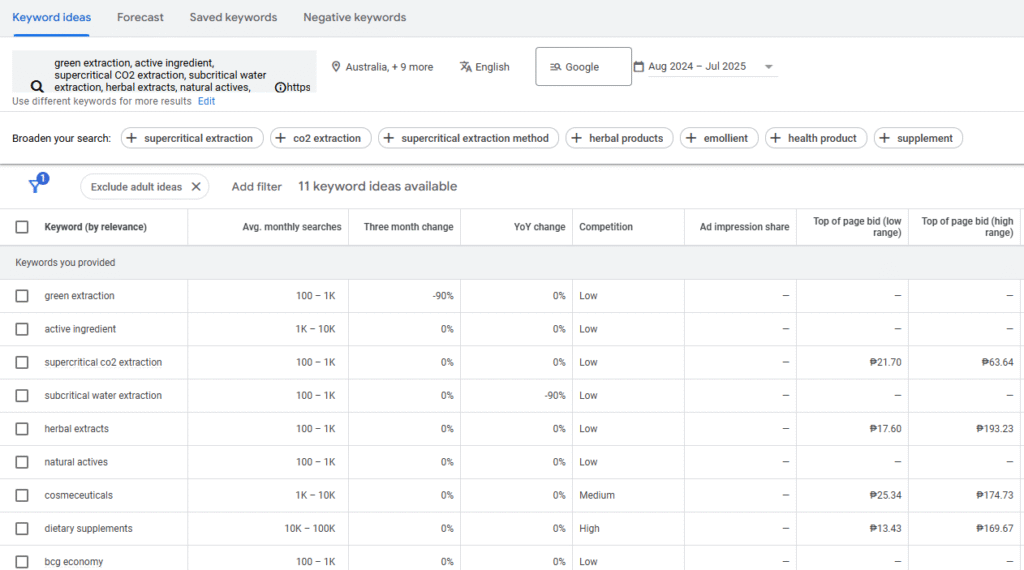

SEO keywords (one line):

green extraction, active ingredient, supercritical CO2 extraction, subcritical water extraction, herbal extracts, natural actives, cosmeceuticals, dietary supplements, eco-friendly extraction, BCG economy, NANOTEC NSTDA

Why Green Extraction, and why now?

Thailand’s health and beauty economy is shifting toward natural, clean-label formulations. Products that feature botanical actives must demonstrate safety for consumers and minimal environmental footprint during production. At the same time, manufacturers need methods that capture more of the desired compounds from herbs and agricultural biomass without petrochemical solvent residues.

NANOTEC responds with Green Extraction, a service built and operated by the Nano-encapsulation Research Group within the Nanotechnology for Quality of Life and Cosmeceuticals team at the National Nanotechnology Center (NANOTEC), NSTDA. The group has developed extraction processes based on green-chemistry principles to obtain more of the target actives while reducing or eliminating hazardous solvents, producing extracts that are safer and more environmentally friendly, and aligning with Thailand’s BCG (Bio-Circular-Green) economy model.

This service is part of NANOTEC’s Strategic Focus on Herbal Extracts, where core competencies include Green Extraction together with downstream encapsulation, formulation, and nanosafety/toxicology capabilities. NANOTEC houses well-equipped facilities for research and development of herbal extracts and acts as a secretariat to the Subcommittee on National Herbal Strategy, underscoring its role in advancing Thai herbal innovation from lab to market.

What we offer: Green Extraction as a service

NANOTEC provides end-to-end R&D service to help industry and research partners obtain high-quality, high-purity natural actives from medicinal plants and other botanical sources using two complementary green technologies:

- Supercritical CO₂ extraction (SC-CO₂).

- Subcritical-water extraction (SWE).

Both approaches avoid conventional petroleum-derived solvents and are inherently safer for cosmetics and dietary-supplement applications. They are particularly suited to clients who need extracts with reduced solvent concerns, better consumer acceptance, and processes that fit environmental, social, and governance (ESG) expectations.

The technologies (what they are and why they matter)

1) Supercritical CO₂ extraction (SC-CO₂)

- Principle. CO₂ is used as the extraction solvent under supercritical conditions. In this state it exhibits liquid-like solvating power and gas-like diffusivity, which helps pull target molecules out of plant matrices efficiently.

- Safety & environmental benefits. After extraction, CO₂ reverts to gas and can be recovered and reused, leaving no petrochemical solvent residues that might concern regulators or end-users. This directly supports cleaner labels and reduced allergy/irritation risk that can accompany residual organic solvents.

- Where it fits. SC-CO₂ is especially suited for non-polar or low-polarity actives commonly sought in cosmetic and supplement applications. The method has been developed at NANOTEC specifically to serve these sectors, making it a practical choice for brands that wish to upgrade ingredient quality while keeping processes eco-conscious.

2) Subcritical-water extraction (SWE)

- Principle. Ordinary water is used as the solvent but operated at subcritical (near-critical) conditions. Under these conditions, water’s properties shift, enhancing its ability to solubilize and extract a broader range of bioactives from plant material.

- Safety & environmental benefits. Because water is the solvent, there is no concern about removing or detecting residual organic solvents, and the process maintains a strong environmental and consumer-safety profile.

- Process advantages. NANOTEC’s researchers highlight that SWE can increase yields of desired compounds and shorten extraction time relative to conventional techniques.

- Where it fits. SWE is well aligned with actives found in widely used Thai herbs. Researchers note its use for commonly applied botanicals such as Centella asiatica (gotu kola) and ongoing R&D with Moringa leaves, both relevant to cosmetics and dietary supplements.

How the service works

NANOTEC designed the service so companies can engage at practical points in their product-development cycle. While each engagement is customized, the typical path looks like this:

- Initial discussion & scoping.

You share your botanical source and your product context (e.g., cosmetic active, dietary supplement ingredient). We discuss feasibility based on SC-CO₂ or SWE, aligned with the BCG-friendly approach and herbal-extracts focus. - Laboratory-scale extraction trials.

NANOTEC performs method development to find suitable operating ranges for your plant matrix using one or both green techniques. Trials focus on achieving higher target-compound capture with reduced solvent risk and improved environmental profile. - Optimization for your use case.

We tune parameters to your desired application (e.g., extract for a cream, serum, capsule, or beverage base), keeping consumer safety and eco-friendliness in view. Because CO₂ can be recycled and water is inherently benign, these processes support claims that matter to today’s buyers. - Pathway toward pilot or production.

As part of NANOTEC’s broader Herbal Extracts strategic focus, your project can connect to additional capabilities (e.g., formulation or nanosafety testing) available elsewhere at NANOTEC. The emphasis remains on Green Extraction, producing cleaner extracts that integrate more smoothly with subsequent steps.

What makes NANOTEC’s Green Extraction different?

- Scientifically grounded & industry-aware. The service is built by the Nano-encapsulation Research Group within NANOTEC’s Quality of Life & Cosmeceuticals program, with researchers who developed the CO₂ and subcritical-water processes internally for real cosmetic and supplement contexts.

- Cleaner extracts by design. No petroleum-solvent residues with SC-CO₂ and water as solvent for SWE align with current expectations for consumer safety and environmental responsibility.

- BCG alignment. The program explicitly supports Thailand’s BCG economy, encouraging processes that are bio-based, circular, and green.

- National role in herbal innovation. Under the Herbal Extracts strategic focus, NANOTEC maintains facilities for R&D of herbal extracts and contributes to national coordination through the Subcommittee on National Herbal Strategy, helping ensure that results stay aligned with Thailand’s long-term herbal-sector direction.

Who this service is for

- Cosmetics & cosmeceuticals brands that require safer, solvent-conscious botanical actives for creams, serums, cleansers, and related formats.

- Dietary-supplement companies seeking extracts with minimized solvent concerns and processes that support clean-label positioning.

- Agrifood and herbal-raw-material suppliers who wish to upgrade their plant materials into higher-value, standardized extracts using greener methods.

- R&D teams and public/private consortia working on Thai herbal value-addition within BCG frameworks.

Typical outcomes you can expect

- Green-extracted samples (SC-CO₂ and/or SWE) suitable for evaluation in cosmetic or dietary-supplement contexts.

- Process know-how on the chosen green method, developed through lab-scale trials targeted to your botanical source.

- Clear alignment with sustainability and consumer-safety narratives, because solvent residues are avoided (SC-CO₂) or not present (SWE).

- A pathway to next steps inside NANOTEC’s herbal-extracts focus (e.g., formulation or nanosafety evaluation available as separate services), helping your team move from concept to market more efficiently.

Frequently asked questions

Q: How do I decide between SC-CO₂ and subcritical-water extraction?

A: It depends on the chemical nature of your target actives and your product format. SC-CO₂ is excellent for non-polar compounds and leaves no petrochemical solvent residue. SWE uses water and is strong for polar actives; it also shortens extraction time versus many conventional methods. In our scoping call we recommend the path (or combination) that best suits your botanical and claims.

Q: Are these methods appropriate for both cosmetics and supplements?

A: Yes. NANOTEC’s researchers developed and applied both methods with cosmetic and dietary-supplement use in mind, to support safety and environmental considerations that customers and regulators expect in these categories.

Q: Do the technologies match Thailand’s sustainability direction?

A: Yes. Green Extraction directly supports the BCG economy model reducing hazardous solvents, recycling CO₂, and using water as the primary solvent in SWE.

How to start

- Contact NANOTEC’s Business Development Unit.

Share your plant source, intended application (cosmetic or supplement), and any constraints you must meet (e.g., solvent-free expectations). - We scope a Green Extraction plan.

We propose SC-CO₂, SWE, or a combined approach that fits your material and business objective. - We execute lab-scale trials and review results together.

You receive the extracted samples and an R&D summary suitable for internal decision-making and for planning subsequent steps with NANOTEC.

Suggested links

- Cosmetics Production (Trial & Commercial). For brands planning to incorporate green-extracted actives into finished products.

- Nanoparticles Production. For clients who wish to explore encapsulation of their green extracts (within NANOTEC’s Herbal Extracts focus).

- Safety & Toxicology Testing Services. For in vitro nanosafety and related evaluations that support product safety dossiers.

NANOTEC’s Green Extraction service gives Thai and regional companies a clean, science-based route to obtain high-value natural actives from herbs and botanicals. By using supercritical CO₂ and subcritical-water extraction, the service raises extraction efficiency while reducing reliance on petrochemical solvents, producing ingredients that align with consumer safety, environmental responsibility, and the BCG vision. Backed by NANOTEC’s Herbal Extracts strategic focus, dedicated facilities, and national coordination roles, Green Extraction is a practical way to raise product value and trust from Thailand’s biodiversity to the global market without over-promising and without compromising on safety or sustainability.