Meta description (140–160): Bring nano-enabled cosmetics to market with NANOTEC’s Cosmetics Production Service trial batches from THB 29,000, ASEAN GMP Cosmetic–aligned workflows, coordinated QC and stability testing, and smooth scale-up to commercial production.

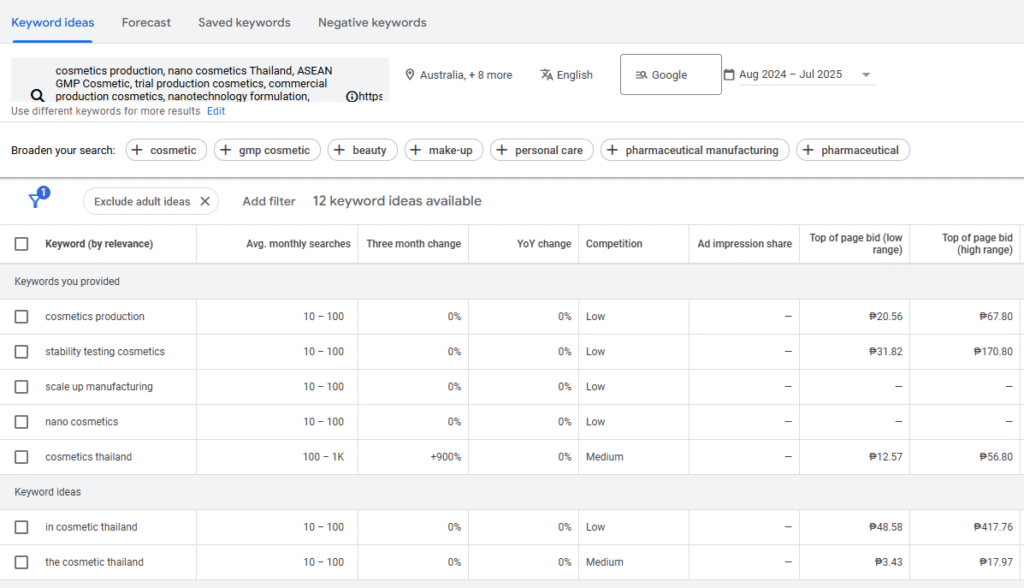

SEO keywords: cosmetics production, nano cosmetics Thailand, ASEAN GMP Cosmetic, trial production cosmetics, commercial production cosmetics, nanotechnology formulation, stability testing cosmetics, microbiological testing cosmetics, scale up manufacturing, NANOTEC production plant

The Nanoparticles and Cosmetics Production Plant at the National Nanotechnology Center (NANOTEC, NSTDA) helps brands and manufacturers turn nano-enabled concepts into finished cosmetic products. We provide trial production for formula screening and market testing, followed by commercial production aligned with ASEAN GMP Cosmetic expectations. In the same ecosystem, you can coordinate physicochemical, microbiological, and stability testing to generate defendable data on quality and shelf life.

Whether you are exploring a new nano-active, refining an existing formula to improve stability or sensorials, or preparing for larger-scale supply, our process is designed to be practical, traceable, and scalable so you can move from idea to inventory with confidence.

Starting fee: Trial Production from THB 29,000 per formula (formal quotation follows scoping).

Why Produce with NANOTEC?

- ASEAN GMP Cosmetic–aligned workflows. Production and documentation are organized with downstream audits and partner reviews in mind.

- Short development loops. Trial batches, QC, and stability can be scheduled together, cutting handoffs and time-to-decision.

- Nano know-how built in. Our facility and staff routinely handle nano-enabled ingredients and can advise on dispersion, process order, and compatibility.

- Evidence you can use. Reports are written for QA and commercial partners: concise, structured, and decision-ready.

- Seamless path to scale. Once a process window is set, we help you scale in-house to commercial production with consistent outputs and traceability.

What We Make

We manufacture finished cosmetic products that incorporate nanoparticles or nano-enabled ingredients supplied by you or produced via our Nanoparticles Production Service. Formulation types are finalized during scoping; typical compositions include emulsion-based products, gels, serums, solutions, and other topical forms for leave-on or rinse-off use. (Exact claims and regulatory positioning remain the brand’s responsibility.)

In addition to making the product, we can coordinate fit-for-purpose QC and stability programs so that your technical file, product specs, and commercial plan progress together.

Our Two-Stage Model

1) Trial Production (from THB 29,000 per formula)

Trial production allows you to test feasibility, optimize process conditions, and collect early QC/stability data before you commit to larger volumes.

What’s included in a typical Trial Production package:

- Scoping & design. We capture product intent, target batch size(s), and constraints (e.g., solvents to avoid).

- Process development. Definition of order-of-addition, mixing regimes, and temperature ranges that protect nano-ingredient integrity.

- One trial batch at an agreed scale suitable for lab testing, panel evaluation, or market seeding.

- Basic QC panel (agreed in scoping), such as appearance, pH, viscosity/rheology checks where appropriate, and a basic microbiological screen.

- Stability plan proposal (e.g., room temperature and elevated conditions, checkpoint intervals) with optional execution.

- Production summary documenting key process parameters and in-process controls for repeatability.

What you can add (quoted as options):

- Additional iterative trial batches to fine-tune feel, viscosity, or aesthetics.

- Expanded physicochemical tests and microbiology (e.g., broader panels when warranted).

- Stability studies (design → execution → report) to project shelf life and define storage statements.

- Compatibility checks, for example, with containers or ancillary raw materials you plan to use.

- Coordination with our Nanoparticles Production Service if your formula uses a new nano-active.

2) Commercial Production (scale-up)

After the trial stage locks the process window and release tests, we schedule commercial batches. The transition includes a scale-up readiness review and a finalized batch documentation set aligned with ASEAN GMP Cosmetic expectations.

Commercial Production usually includes:

- Pre-production review. Confirmation of raw-material specs, nano-ingredient COA, and process parameters.

- GMP-aligned manufacturing. Executed under SOPs with traceability from raw materials to finished lots.

- Release testing per your agreed specification (physicochemical + microbiological).

- Batch documentation (e.g., batch record summary, materials traceability, release results).

- Retention samples and stability continuation if scheduled.

Optional at commercial stage:

- Ongoing stability (real-time and/or accelerated) with periodic summaries.

- Incremental process optimization if you choose to pursue cost, throughput, or sensory refinements over time.

End-to-End Workflow

- Inquiry & NDA (as needed). We can work under your confidentiality terms.

- Technical scoping. Define objectives, target pack sizes for sampling, constraints, and the role of nano-ingredients.

- Quotation & plan. Receive a transparent proposal covering Trial Production, optional testing, and a high-level scale-up path.

- Trial Production. Execute the trial, run the agreed QC panel, and prepare a production summary.

- Decision point. Review data; choose to iterate, to proceed to commercial, or to adjust the plan.

- Commercial Production. Manufacture at scale with release testing and documentation.

- Post-batch support. Stability readouts as scheduled; optional tweaks and continuous improvement.

Quality, Safety & Documentation

- ASEAN GMP Cosmetic–aligned practices for cosmetic manufacturing.

- Traceability: material IDs, lot numbers, and process parameters retained in the batch documentation.

- Integrated testing: we can coordinate physicochemical, microbiological, and stability tests in the same ecosystem to reduce transfer risk.

- Clear reporting: decision-ready summaries your QA and commercial counterparts can understand quickly.

Note: NANOTEC provides production and testing services. Regulatory submissions and marketing claims are the responsibility of the product owner; we supply technical evidence packages to support your internal reviews and partner discussions.

Typical QC & Stability Options

We don’t force a fixed panel; instead, we right-size testing to the risk and decisions at hand. During scoping we’ll propose a program, which may draw from:

- Physicochemical tests relevant to the form (e.g., appearance, pH, viscosity, density; additional tests as appropriate to the product type).

- Microbiological screening aligned to cosmetic manufacturing needs.

- Stability studies with defined storage conditions (ambient and elevated) and checkpoints to observe changes in appearance or other agreed attributes.

- Follow-on analytics, when indicated, can be coordinated via NANOTEC laboratories (e.g., particle size, chemical identity, surface/wettability assessments) to troubleshoot or verify performance.

(Exact methods and acceptance criteria are finalized in your test plan and reflected in reports.)

Pricing Overview

- Trial Production (nano-enabled cosmetic formula): from THB 29,000 per formula

- Commercial Production: quoted after trial stage, based on batch size, documentation depth, and release test scope.

What You Provide

To keep timelines tight and outputs on target, please prepare:

- Product intent (use case, target market, and any constraints such as “avoid X solvents”).

- Raw materials (and COAs) if you supply them; otherwise we’ll propose sourcing.

- Nano-ingredient details: source, form, and desired concentration (or request our Nanoparticles Production Service).

- Target specs you care about (e.g., appearance window, pH range) and any legacy learnings from prior trials.

- Labels/claims are owned by you; we can align testing to support your internal acceptance criteria.

Frequently Asked Questions

- Is the starting fee enough to finalize a product?

The THB 29,000 fee covers one trial batch with a basic QC panel suitable for feasibility and internal review. Many teams complete one to three iterations before locking specs for commercial production. - Do you formulate from scratch or only manufacture?

We can co-develop process parameters around your base formula and nano-ingredients, or manufacture to your formula. If your nano-active is not yet finalized, pair this service with our Nanoparticles Production Service. - Can you help estimate shelf life?

Yes. We design and execute stability programs and provide interim and final readouts that you can incorporate into product files and partner communications. - What about safety and toxicology?

If you need in-vitro data to support internal reviews, we can coordinate Cytotoxicity (ISO 10993-5) and In-vitro Micronucleus (OECD 487) testing through our Safety & Toxicology Testing services.

Who This Service Is For

- Brands and startups preparing market-test batches or transitioning a lab concept to real-world supply.

- OEM/ODM manufacturers seeking ASEAN GMP Cosmetic–aligned production for nano-enabled formulas.

- Distributors/private labels who need traceable manufacturing and organized documentation.

- R&D teams that want trial-to-commercial continuity without re-learning processes at each stage.

Suggested Internal Links

- Nanoparticles Production Service – produce your nano-actives or nano-enabled raw materials before formulation.

- Safety & Toxicology Testing

- Thermal & Stability Testing Hub – design and manage stability studies and interpret shelf-life evidence.

Ready to plan a trial batch?

Share your formula intent, nano-ingredient details, and target batch size. We’ll return a clear plan and quotation so you can move from pilot to commercial production without losing momentum.

Contact Us

National Nanotechnology Center (NANOTEC)

Infrastructure Services

143 INC 2 (B), Thailand Science Park, Phahonyothin Road,

Khlong Nueng, Khlong Luang, Pathum Thani 12120, Thailand

Tel. +66 2 564 7100 ext. 6517, 6625, 6680

Email: bdis-infs@nanotec.or.th